Applications

Georgia Glassfiber supplies fiberglass materials in Georgia and the Southeast, sourced from Uzbekistan. Below are common use-cases and where these materials are typically applied.

Fiberglass Materials

Glass mat cloth is a non-woven fiberglass material bonded with a polymer binder. It’s practical to work with, non-combustible, and it does not provide a nutrient medium for microorganisms. In many finishing jobs, it’s an affordable way to reinforce wall surfaces across large areas.

A key characteristic is density. Common painting applications often use mid-range densities that balance strength with good adhesive penetration.

Common base surfaces:

- Gypsum or cement-sand plaster

- Drywall systems

- Tongue-and-groove slabs (TGS)

Main purpose in finishing work: helping reduce the appearance of microcracks after the final finish (paint or decorative coatings).

Also used to:

- Improve uniformity of the base surface

- Simplify leveling before final putty/finish layers

- Increase crack resistance at drywall joints

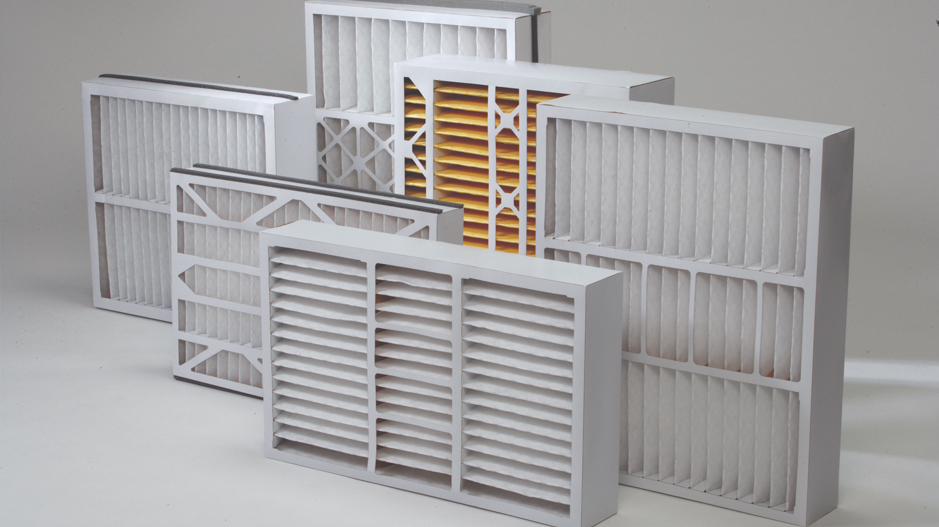

Glass-mat-based filtration media can be used for filtering air and liquids. A common example is floor filtration in paint booths (automotive, furniture, and industrial finishing), helping protect exhaust ventilation systems from aerosols.

Fiberglass filters are also used in labs and industrial processes either as a primary filter or as a pre-filter to reduce load on a main filter element.

These materials are valued for chemical stability, temperature tolerance, corrosion resistance, and mechanical strength, which is why they show up across chemical processing, petroleum handling, pharmaceutical workflows, water treatment, and metalworking environments.

Typical advantages:

- Low resistance

- Practical and safe for industrial environments

- Non-combustible material

Glass mat is commonly used to reinforce and improve the performance of bitumen roofing systems, membranes, and flexible tile products used in both residential and commercial construction. As a base layer in waterproofing materials, it supports weather protection, resistance to seepage, and long-term service life. It can also contribute to improved sound and heat insulation performance in certain builds.

Product characteristics often include:

- Consistent fiber distribution

- Good tensile strength

- Good tear strength

- Good compatibility with asphalt/bitumen systems

Glass mat used with thermosetting resins is commonly applied in composite manufacturing—especially for the first layer of pipes or tanks that may contact water or other liquids. It helps improve compressive strength, resistance to permeation, and overall service life.

Because it drapes well and absorbs resin quickly, glass mat is often preferred for products with complex geometric shapes.

Product characteristics often include:

- Consistent fiber distribution

- Smoother finished surface

- Good molding properties

- Efficient resin uptake

Glass mat is used in anti-corrosion wrapping systems for steel pipelines (often underground) used for transportation of water, oil, gas, and other media. When paired with appropriate protective compounds, it can provide strong resistance to penetration and help extend service life.

Material specifications and suitability depend on the application and the protective system being used. If you have a specific use-case, we can help identify the right fit.

Product characteristics often include:

- Consistent fiber distribution

- Good tensile strength

- Good tear strength

- Good flexibility

Fiberglass mat can be used as reinforcement for carpet tiles, carpet coverings, and certain flooring products. It helps maintain dimensional stability, reducing shrinkage and deformation over time.

Because of its stability, floor coverings can lay flatter even under variable temperature and humidity conditions.

Product characteristics often include:

- Consistent fiber distribution

- Smooth surface

- Good tensile strength

- Good tear strength

- Good flexibility

- Good dimensional stability

Certain fiberglass mats are used as a substrate for plastic floor and wall coverings, including PVC and vinyl systems. In finished products, this can support a smoother appearance and stable sizing with reduced shrinkage or deformation.

With further processing, similar substrates may also be used to create lining materials for interior finishes in commercial spaces.

Product characteristics often include:

- Consistent fiber distribution

- Smooth surface

- Good tensile strength

- Good tear strength

- Good flexibility

- Good dimensional stability

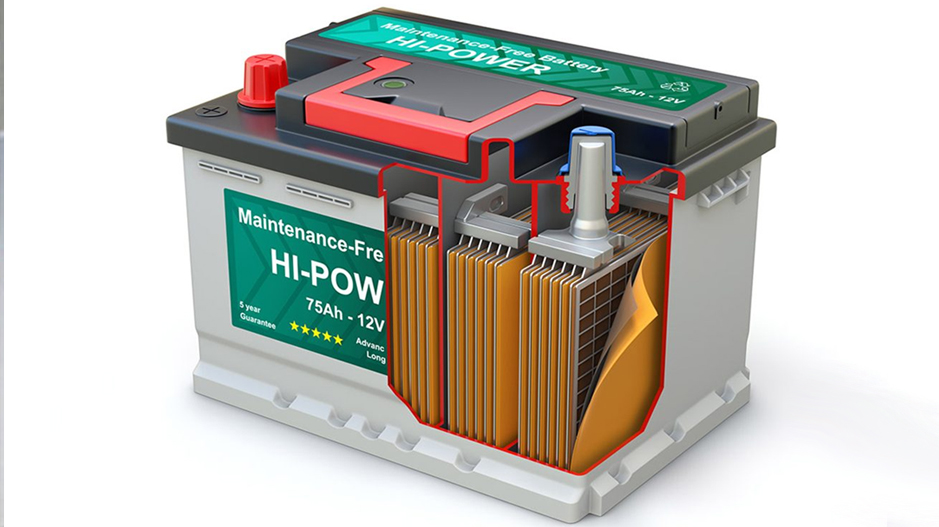

Glass-fiber-based separator media is used in certain lead-acid battery designs. In composite separator configurations, it can support vibration resistance, reliable starting performance, and long service life.

Product characteristics often include:

- Uniform thickness

- Good liquid absorption

- Acid resistance

- Consistent surface quality

Glassmat Plita Systems

Glass-mat-faced gypsum panels (often referred to as Glassmat Plita) are used as facade panels and exterior sheathing in commercial and residential buildings. They may be used as a paint-ready surface or behind a range of exterior claddings including brick, stone, metal, wood, and vinyl.

These systems are commonly selected for moisture and mold resistance, durability, sound dampening, impact resistance, and fire performance—depending on the full wall assembly.

Panel sizes and installation methods typically align with standard gypsum sheet workflows.

A ventilated facade is a multi-layer exterior wall structure that typically includes:

- a supporting subsystem (aluminum, stainless steel, or galvanized steel)

- one or two layers of thermal insulation

- wind/moisture protection membrane where required

- exterior cladding that protects the wall system from weather exposure

An air gap between cladding and insulation allows moisture to evaporate and reduces the chance of trapped condensation in the system.

Ventilated facades are valued for efficient installation, reduced need for wall leveling, and ease of replacing individual damaged sections during repairs.

In certain frame and hybrid structural systems, exterior wall assemblies may use a galvanized metal frame with insulation in the cavity and glass-mat-faced gypsum panels as the outer sheathing layer. Seams are typically treated with appropriate tape/mesh and coatings before final finishing.

The exact assembly depends on local codes, insulation requirements, and finish goals. If you share your application, we can help match product options to your build approach.

Glass-mat-faced gypsum panels are used in certain fire-rated interior applications such as protected corridors and elevator shafts. Depending on the rated assembly, these materials can contribute to fire resistance and reduced flame spread and smoke development.

Always verify the full wall assembly and rating requirements with your contractor, architect, and local code requirements.